5 Key Electronic Product Design Challenges That Need to be Addressed

Electronic product design is much more streamlined today than ever. As an electrical engineer, you can leverage various readily available resources and toolsets, such as embedded code generators, off-the-shelf sensors, and single-board computers to accelerate design and development. Despite these advancements, you may still face challenges with key project aspects, including schedules and costs. Here are five such examples.

1. Unrealistic Project Goals

Embarking on any project with unrealistic or overly-ambitious goals may increase the chances of failure. This can occur when your goals aren’t clearly defined or keep changing.

Often, unclear use cases or missed requirements have detrimental effects on delivery. These issues can cause costly design churn and delay your project.

Also read: How to Select High-Accuracy Ultra-Low Pressure Sensors

2. Inaccurate Time, Cost, and Risk Projections

Incorrect project estimates can lead to unrealistic expectations. Often, unpleasant surprises, including extra costs and schedule overruns, are due to the inaccurate cost and time estimates.

It’s easy to make this mistake when your electronic product design project seems simple in theory. Proper risk analysis is also vital to avert failure, especially when working with high-risk technologies.

You should account for the potential impact of any unforeseeable events on project execution.

3. Optimizing RF Systems

Choosing the wrong RF technologies is one reason why some designers have to go back to the drawing board to address any issues, such as potentially expensive project costs.

While bleeding-edge solutions may be the most advanced options out there, experienced engineers know better than to use those in their applications.

The best RF options should match your application’s performance requirements. Before selecting any, assess how it may impact costs for implementation, data rates, and infrastructure robustness.

4. Regulations and Cellular Compliance

Sometimes, regulatory and cellular network certification processes can adversely impact electronics product design and development plans.

For example, approval delays can occur in applications where physical volume is a major constraint.

Even with the use of a pre-certified module on the PCB in these cases, the certification process takes a long time because the PCB isn’t board-approved yet.

Regulatory compliance is another obstacle to the successful completion of electrical engineering projects.

Issues related to radiation and other emissions often emerge during FCC or UL testing, pushing project timelines further back. These regulatory bottlenecks can introduce unexpected costs.

Also read: Understanding How Digital Signal Processing Works

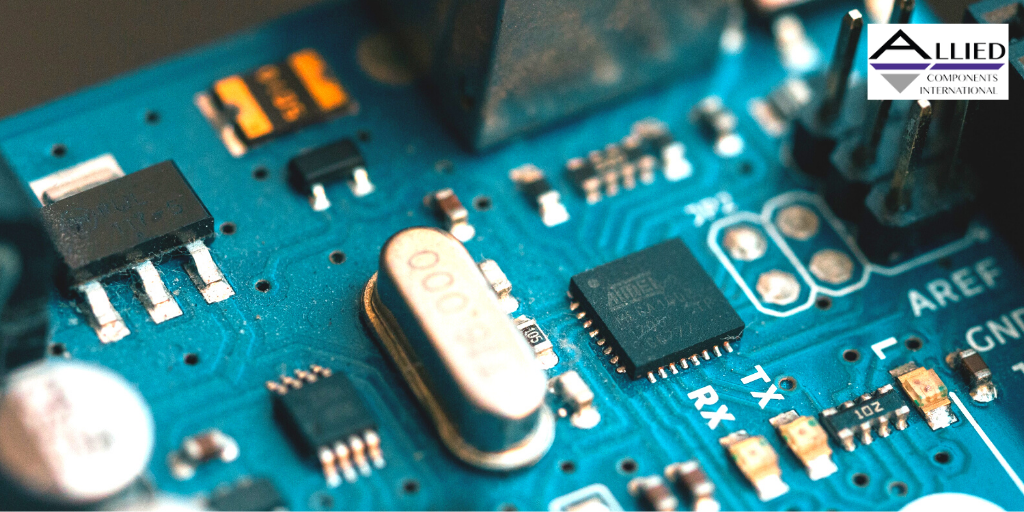

5. Working with High-Density Electronic Components

Optimal integration of various components in high-density electronic circuits poses a significant engineering challenge. Designers must make key tradeoffs to optimize performance, space, and costs.

They have to address power consumption, heat management, and other issues related to high-density board design.

When you’re an engineer, you should be prepared to address numerous challenges to complex electronic product development. Visit us at Allied Components International for a broad range of superior performance, efficient magnetic devices, and systems.