How to Select High-Accuracy Ultra-Low Pressure Sensors

The popularity of board-mounted ultra-low pressure sensors keeps rising day by day. They provide high accuracy and superior performance in a broad range of applications, from ventilators and dialysis machines to medical chemistry and VAV (variable air volume) control systems. Learn more about their benefits and how to select the right low-pressure sensor for high-precision readings.

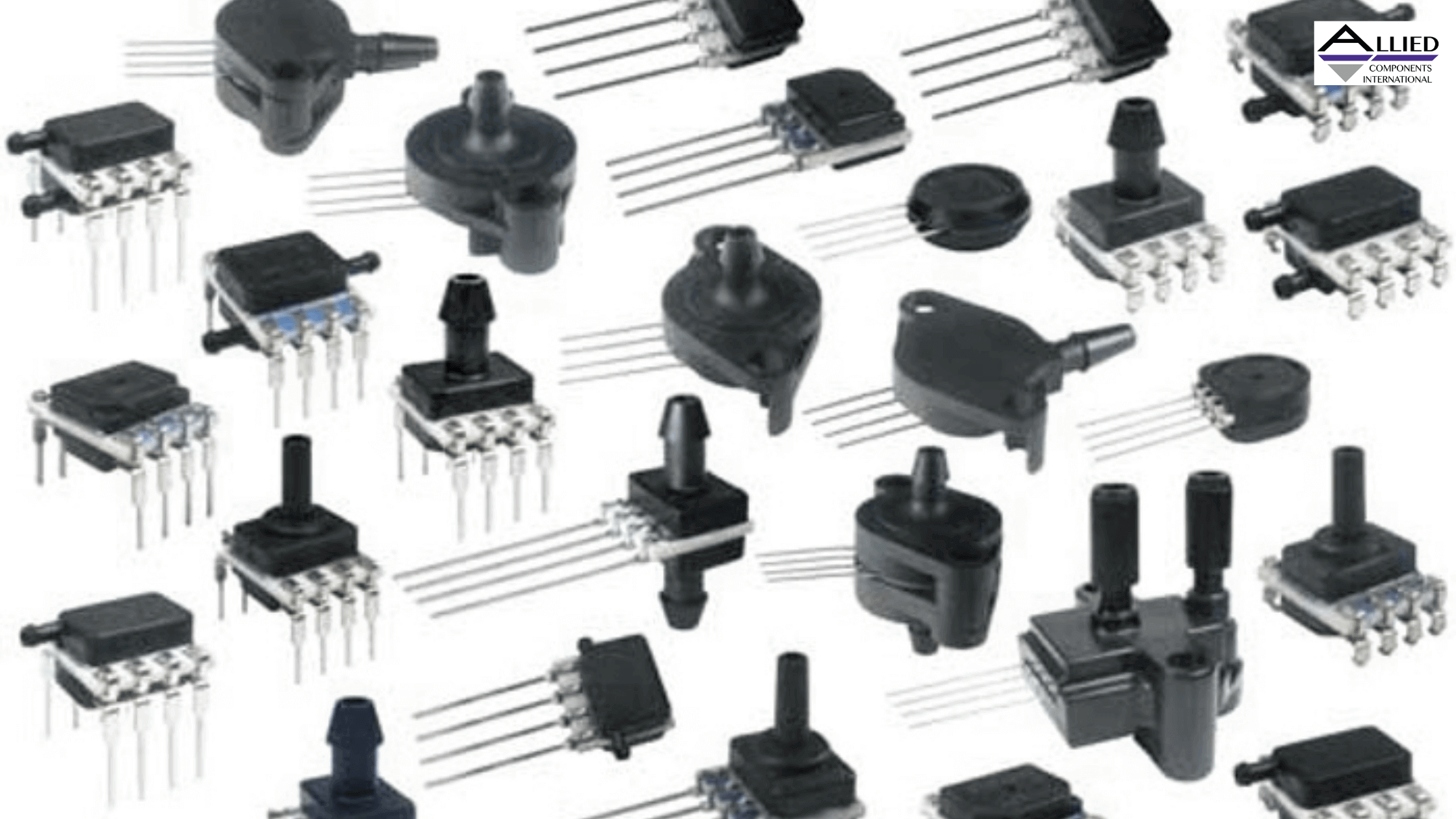

Advantages of Board-Mounted Pressure Sensors

- They can detect minimal pressure changes, providing accurate readings

- Easy implementation due to their direct integration into equipment’s electronics assembly

- Significant space savings due to their compact size

- High energy efficiency

Highly Accurate, Ultra-Low Pressure Sensors in Medical Applications

These devices are a popular choice for many medical applications, including:

- Hemodialysis equipment: The sensors accurately measure and help control the pressure of blood flowing in and out of the patient’s body during dialysis. They also improve patient safety and treatment efficiency.

- Ventilators: In these medical machines, the sensors’ accuracy in detecting ultra low-pressure changes helps track a patient’s breathing patterns and detect clogged filters.

- Anesthesia equipment: These machines require high-precision pressure detectors to keep air and oxygen pressure within safe operating parameters.

- Continuous positive airway pressure (CPAP) machine: Board-mount high-accuracy pressure sensors are used in sleep apnea therapy to ensure the steady and safe flow of oxygen into the patient.

- Chemistry analyzers: In this medical field, the sensors have several applications. In pipettes, they’re used to measure the volume of fluid drawn or detect misplacement of the vial, etc.

Other Use Cases for Ultra-Low Pressure Sensors

- Tracking filter efficiency in green building systems

- Automated control of airflow or window position based on pressure changes in a building

- Incorporation in VAV systems to regulate airflow rate throughout a building

- Barometry

- Gas flow instrumentation

- Pneumatic control

- Gas chromatography

- Flow calibrators

How to Choose a Board-Mount Pressure Sensor

Important considerations include:

- The need to optimize system uptime when the sensor is consistently exposed to high working pressures and burst pressures

- Full Scale Span, Best Fit Straight Line (FSS BFSL) accuracy

- A low Total Error Band (TEB) improves system accuracy, allows sensor interchangeability, and optimizes manufacturing time and cost

- High-stability board-mount pressure sensors help maximize system performance

- Portable energy-efficient sensors extend battery life (some include energy-saving options like sleep mode)

- Moisture Sensitivity Level (MSL) 1 pressure sensors simplify and enhance the safety of solder reflow attachment and repairs

Demand for Ultra-Low Pressure Sensors

Today, on-board mounted devices are the go-to option for engineers looking to build high-accuracy, ultra-low pressure sensor solutions. Many of the superior-performance products on the market provide full calibration and optimal temperature compensation. Not only are these sensors available in broad pressure ranges, but they also support multiple pressure measurements, such as:

- Absolute pressure

- Differential pressure

- Gage pressure

Visit our Allied Components International page today to explore our cost-effective board-mount electronic products.