What Types of Magnetic Core Materials Are Used in Transformers?

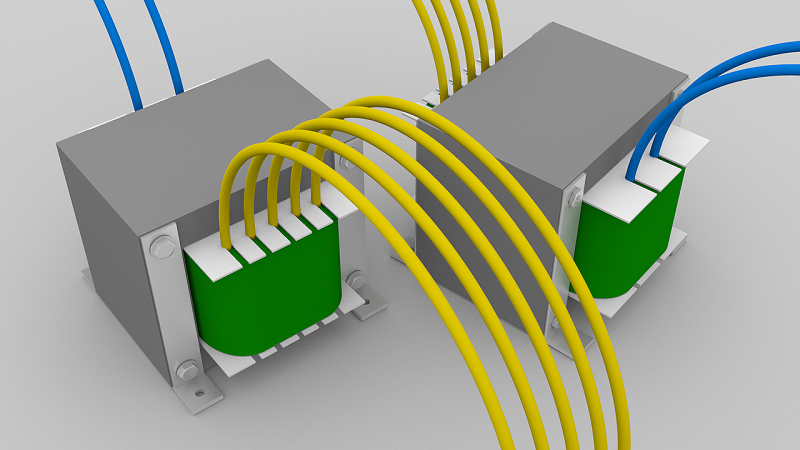

The magnetic core of an electrical power transformer comprises primary, secondary and tertiary windings. With primary windings on one side and secondary windings on the opposite, magnetic flux in between is what connects them on the core, allowing current to flow.

Here are the types of materials used for cores to create a pathway for magnetic flux:

Amorphous or Vitreous Metal This metal is glassy or non-crystalline, making it useful for high performance transformers due to low conductivity.

Amorphous Steel One of the most widely used core materials in transformers, this steel has minimal losses compared with other cores. It's practical for high temperature / high efficiency / medium frequency transformers.

Carbonyl Iron Core Composed of powdered carbonyl iron with small iron spheres, this core can be used for various magnetic flux and temperature levels, allowing stable service. The iron spheres are coated with a layer of thin insulation, reducing the effects of eddy currents at high temperatures.

Ferrite Ceramics These magnetic cores are based on iron oxide and one or more metallic substances, making them useful for high frequency equipment and insulation efficiency as they help reduce eddy currents. There are a variety of specifications for various electrical requirements.

Laminated Magnetic Core Thin iron sheets covered with insulation layers in these cores create a reliable solution to block eddy currents. The localized currents are restricted to narrow loops within every lamination layer.

Silicon Steel This material produces high electrical resistivity and long-term performance stability, which is why it is used for high performance applications. It also provides high saturation flux density. In recent years, it has been modified chemically, resulting in a new solution known as AISI type M6, which is characterized by high permeability and low losses.

Solid Iron Core By providing magnetic flux, this core helps facilitate high magnetic fields without iron saturation. Typically this material is reserved for DC applications due to the prevalence of significant high temperatures and high frequency eddy currents generated from the magnetic field.