The Brown Out Reset in Microcontrollers: Preventing False Power-Downs

Exploring the world of microcontrollers inevitably leads to learning about problems that affect circuits, such as a "False Power-Down." This situation involves problems resulting from a combination of power level, external signals, multiple power supplies in a circuit and slow-discharging capacitors. Here's a deeper look at how to avoid a False Power-Down.

False Power vs. New Designs

Designers use False Power as an option to Brown Out Reset (BOR) and its successor, Low Voltage Detect (LVD). When a False Power source is elevated high enough and applied directly to a GPIO pin via the ESD protection circuit, it can cause problems. Experts believe it's best to avoid BOR in lower on-power situations, due to its excessive energy consumption. BOR is usually activated by a bit in a control register.

Increasing Microcontroller Reliability with BOR

When a microprocessor experiences a brown out there is a short-term reduction in power supply voltage lower than what's necessary for reliable operation. An effective tip for making a microcontroller more reliable after its start-up is to use BOR, a solution often chosen to solve power supply issues. It's common for microcontrollers to have a protection circuit that measures the supply voltage and resets itself when it detects low voltage levels.

When a BOR triggers a reset, the result is that a status bit is set. The status bit may not be effective if the power falls too low. Furthermore, the BOR can be disabled by insufficient power supply. In between operable and inoperability is a "danger zone" where unpredictable problems may occur. It's possible for the device's power to fluctuate in this danger zone for many years and then cease to work one day.

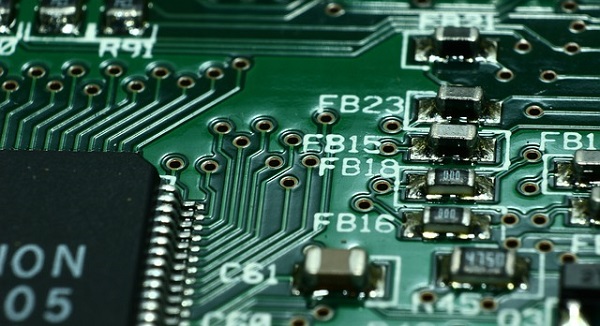

An example of a circuit design containing a microprocessor involves placing the microprocessor near the center of the circuit board. It's located near 18 mounted voltage regulators. Both modules and sensors are mounted on water cooled plates designed to transfer heat.