Smart Meter Design: Component Options That Improve Their Operation

Smart meters are here to stay and are playing a big role in big data, particularly with utility companies. One of the reasons that this technology is becoming widely used by utilities is that they can monitor and regulate energy conservation. Here's a brief look at how smart meters are paving the way toward more robust circuit protection components and power control components.

What Smart Meters Can Do

Advanced Metering Infrastructure (AMI) facilitates the Internet of Things (IoT). Major advantages to this modern system include remote monitoring and fault detection capabilities.

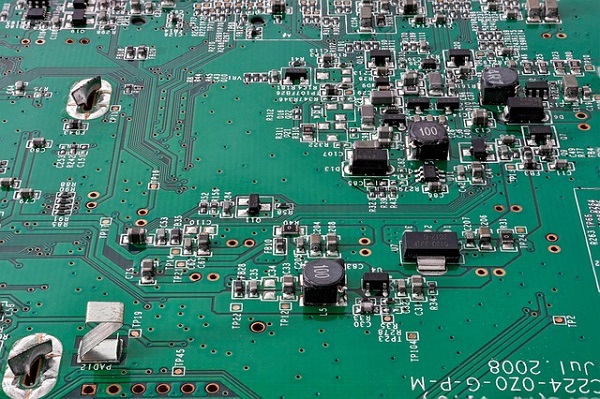

But like the older meters, the new technology requires durability, accuracy, sensing, circuit protection components and power control components. Sensing components are used to measure water and gas flow. Smart meters also contain tamper-detection components that prevent customers from trying to modify electrical usage data. Power control components also embody load switching and energy pulse-out features with solid-state relays (SSRs). Some smart meters use power MOSETs for input voltage and step down functions.

Surge and Transient Protection

Increased use of overcurrents are needed to protect against electrical transients (ESD) that originate from the electrical grid, which can be affected by lightning and other disruptions. Due to this fact, engineers have designed smart meters that include Metal Oxide Varistors (MOVs) with high voltage ratings to counter AC line voltage. MOVs effectively protect input power circuitry.

The MOV reacts to temporary excessive overvoltage transients by adjusting to a steady appropriate voltage. Smart meters may also have a built-in safeguard against overheating, smoke and fire when unusual sustained overvoltage occurs. This safety component is called a thermally protected varistor (TMOV).

MOV Limitations

Even though a MOV provides protection against surges and transients, it only has a certain lifespan, which introduces risks that may cause damage to circuits if not periodically inspected. A MOV can only handle a finite number of surges before ceasing to function. Factors to consider include MOV disc size, surge magnitude and how long the system is projected to last, which can be 10-20 years or more. The bigger the disc size, the longer the component will typically last.