Isolated Vs. Non-Isolated Power Converters: A Technical Comparison

Isolated power converters have various uses, such as medical equipment where safety is extremely important. Galvanic isolation is also considered if the system requires the elimination of issues like signal noise or communication errors. Here’s a look at isolated vs. non-isolated power converters and factors to consider when choosing either system.

Understanding Isolated and Non-Isolated Power Supplies

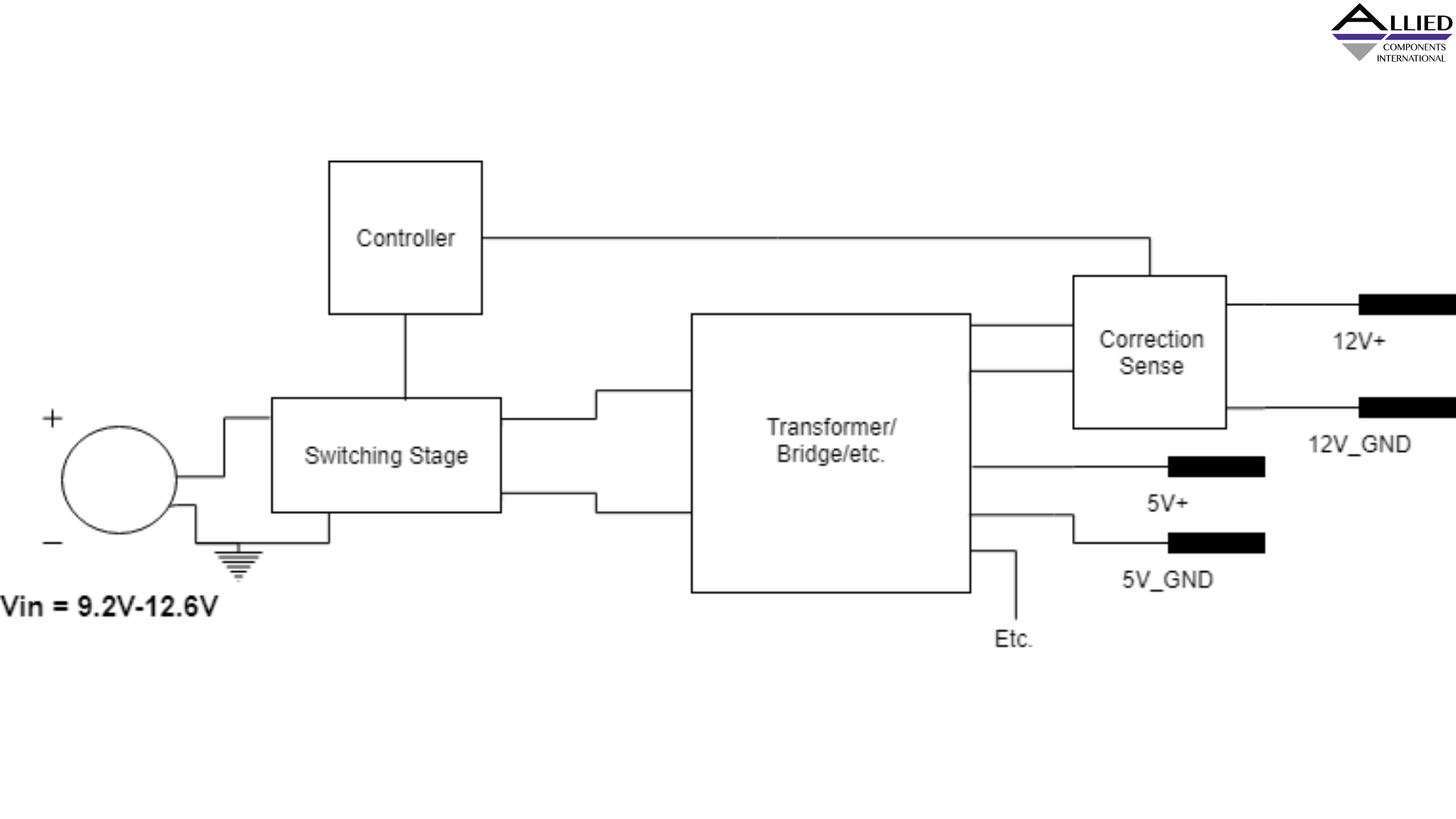

Isolation in a power converter: In this system, a transformer is used to physically and electrically separate the circuit into two sections. The current won’t flow between input and output due to this separation.

Non-isolated power converter: Flow of current between input and output is possible because there’s only one circuit.

How Galvanic Isolation Works

Input and output use the same ground reference in a non-isolated circuit. However, separating the power converter circuits creates two sections, each of which has its own ground. To transfer power between the isolated input and output sections, you may typically use:

- Transformers or

- Coupled inductors

Signal can be transmitted across the isolated circuits through:

- Signal transformers

- Opto-isolators

Important specifications for an isolated power converter include:

- Isolation voltage: This is the voltage that can briefly cross the isolated circuits without causing input-output current flow.

- Working voltage: This is the highest voltage that may continuously cross the isolated circuits without triggering input-output current flow.

When to Use an Isolated Power Converter

You can use isolation in power applications that prioritize factors such as:

Safety Considerations

When designing an AC-DC converter, for example, you can use isolation to meet safety requirements for the device. Isolation would prevent dangerously high voltages from AC mains from crossing to the output section.

Eliminating Ground Loops

Since the input and output circuits don’t have a common ground, it’s possible to get rid of ground loops. Breaking ground loops can eliminate noise that’s ordinary in certain systems.

Floating Outputs

Floating outputs can be achieved by shifting reference voltages in isolated circuits. Typical applications of these power supplies include:

- Mass spectrometers’ detectors

- Anode-grounded X-ray tubes’ filaments

- Suppressor electrodes

When to Use Non-Isolated DC to DC Converters

You may use a non-isolated DC to DC converter when the following factors are a priority:

Cost

Isolation may increase the cost of a power supply system due to the inclusion of components like:

- Custom transformers

- High insulation levels

- Opto-couplers

Non-isolated systems are also cheaper to build because they don’t require these extra components.

Compactness

Additional components increase the size of the power converter. Therefore, non-isolated converters are smaller than their isolated counterparts.

Efficiency

Non-isolated design is more efficient as it allows the direct sensing of the output. Without isolation components like transformers, it’s easier to regulate the output and optimize transient performance. These are the main factors to consider when choosing between isolated vs. non-isolated power converters. Whether your priority is efficiency, compactness, or cost, visit us at Allied Components International for top-tier electronic devices.