How Total Harmonic Distortion (THD) Impacts Power System Efficiency

High total harmonic distortion generally reduces the efficiency of power distribution systems. It usually must be corrected in power systems for non-linear loads like computers, switch-mode power supplies (SMPS), fluorescent lighting, and photocopiers. Here’s a look at how THD impacts power factors and ways to compensate for it.

Power Factor in Purely Sinusoidal Power Systems

There’s no need to consider total harmonic distortion in power systems where the voltage and current have a purely linear (sinusoidal) relationship. In this case, the voltage/current phase shift dictates the power factor. For a purely resistive load, the power factor would be 1. However, power factor correction would be necessary for a sinusoidal circuit with capacitive and/or inductive components in addition to resistive parts. This can be achieved by incorporating a device with the opposite amount of reactance in the power system, offsetting the circuit’s existing reactance.

THD and Power Factor in Non-linear Loads

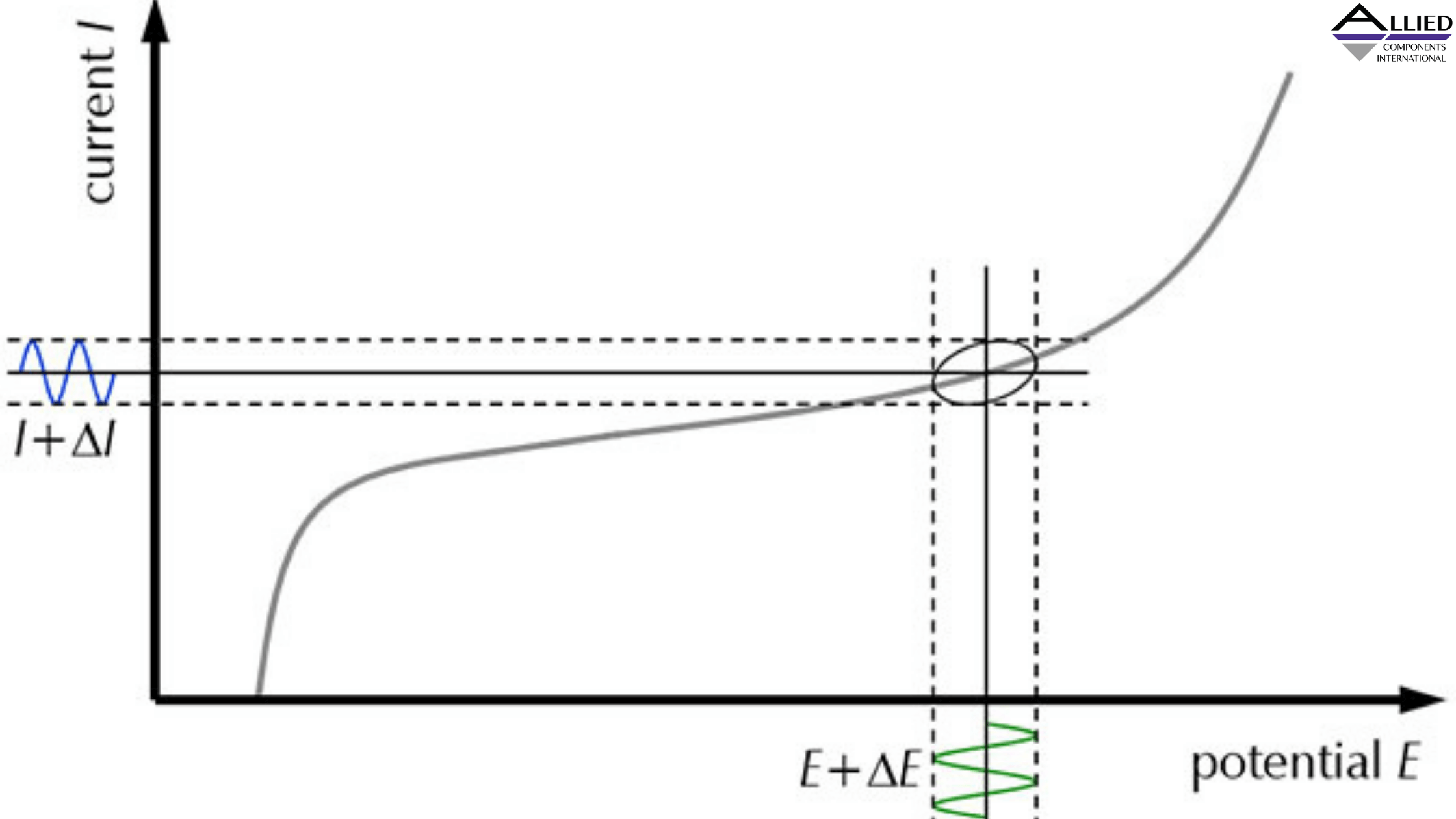

For non-linear loads, you can only optimize power system efficiency by adjusting both the displacement factor and THD total harmonic distortion. These types of loads have harmonic currents, meaning that the current drawn has a different waveform from the supply voltage.

Accounting for Distortion Factor and THD

The total harmonic distortion of the current causes the distortion factor. Therefore, to calculate the power factor for non-linear loads, you should multiply the displacement factor by the distortion factor.

Compensating for THD Distortion in AC/DC Conversion

Most industrial and consumer electrical systems incorporate some form of power conversion, making them non-linear loads. These generally include resistors, capacitors, or inductors. AC/DC converters usually experience high levels of current distortion. Therefore, they would be highly inefficient for large-scale power distribution systems without adequate provisions to correct harmonic distortion. For systems that have AC/DC converters, power factor correction has two main objectives:

- Minimizing the phase shift between the voltage and current (displacement distortion correction)

- Minimizing current harmonics (THD power factor correction)

You can improve the power factor for such systems by adding a boost Power Factor Correction (PFC) converter in the circuit. For example, if the improvement results in a THD of 0.2 (20%) and a phase difference of 3 degrees, the system has a power factor of 0.979.

Thus, the PFC introduces significant improvements in the electrical system’s total harmonic distortion power quality. However, not taking THD into account in the calculations would incorrectly yield a power factor of 0.999. While this figure indicates a highly efficient power distribution system, it would be incorrect because displacement distortion isn’t the only power factor determinant in non-sinusoidal loads line AC/DC converters.

Power factor correction for any electrical distribution system should account for both the displacement and distortion factors. For high-efficiency components like transformers and power inductors, visit our Allied Components International website today!