How to Choose the Perfect Aluminum Electrolytic Capacitor

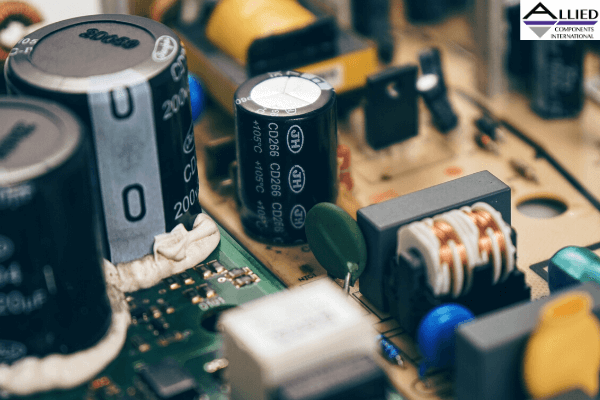

Any given electronic circuit may include aluminum electrolytic capacitors, which are essential components of electrical designs. They offer high capacitance per volume, low impedance values, and are ideal for both storage and high energy capacity.

How Aluminum Electrolytic Capacitors Are Used

Commonly found in power supplies and inverters, aluminum electrolytic capacitors can be used in any electronic system. They are useful due to efficiency for energy storage or reducing unwanted frequencies. This technology keeps changing due to new ideas for materials and improvements in the production process. They've become much more robust and reliable, as good quality units can last up to 20 years.

One of the purposes of a capacitor is to store energy in an electric field until the current is activated. It encompasses two electrodes made of electrically conductive material separated by an insulator made of paper and a conductive liquid called an electrolyte.

Also Read - How to Buy Capacitors: Important Things You Should ConsiderAn electrochemical reaction generates an oxide layer in the anode electrode, which acts as a dielectric or insulator. As an insulator, charges do not flow through its material. At the same time, it has the capacity to transfer the electric force. A major benefit to an aluminum electrolytic capacitor is that it provides ample capacitance per unit of volume for the application's voltage rating.

Here are important facts to keep in mind when searching for the right aluminum electrolytic

capacitors: Also Read - Understanding Capacitor Leakage Current and How to Reduce ItProper Selection of Aluminum Electrolytic Capacitors

The selection criteria should include the application's load condition, along with operating voltage as major considerations. Other factors include surge, transient voltages, and ripple current. It's important to also consider ambient temperature and cooling conditions, as well as how much the application will be used.

Also Read - Different Types of Capacitors: An OverviewYou should stay within the required voltage range to avoid high equivalent series resistance (ESR), which can dissipate power inside the capacitor. ESR acts as a resistor and depends on frequency and temperature. The higher the ESR, the more heat and shorter lifespan of the capacitor. Power may be further lost as a result of heat from a ripple current, in which sometimes you must choose a capacitor with higher ratings than what's required for capacitance and voltage.

The main keys to deciding on the right capacitor involve checking design specifications for required capacitance, expected ambient temperature during operation, expected ripple current, and estimated capacitor life. You should further consider if the application requires a heat sink, forced air, or natural cooling of the capacitor.