5 Factors You Should Consider When Selecting an Inductor

The purpose of inductors in electrical systems is to oppose currents passing through them. Usually they are needed for signal processing and analog currents, except in Switch Mode Power Supply devices (SMPS), in which they provide energy storage.

You must consider the following five factors before deciding the type of inductor that works best for a given application:- Circuit Requirements and Inductor Performance An engineer needs to decide on inductor type from reviewing application requirements if an inductor meets circuit requirements and if the inductor boosts performance. Most of the time inductors are necessary for power circuits or to prevent Radio Frequency (RF) interference.

- Power Circuit Applications When an application includes power circuits, incremental and maximum currents should both be considered. Incremental current is the current level when inductance is lowered while maximum current applies to when the current level surpasses the temperature of the application device.

- RF Considerations

When an inductor is needed for an RF application, you must keep two factors in mind:

- Q factor (quality), which relates to the inductor's resistance value. High Q factor is always the more ideal value.

- Self-Resonant Frequency (SRF), which is the frequency when the device ceases its role as an inductor. You must always select minimum SRF value.

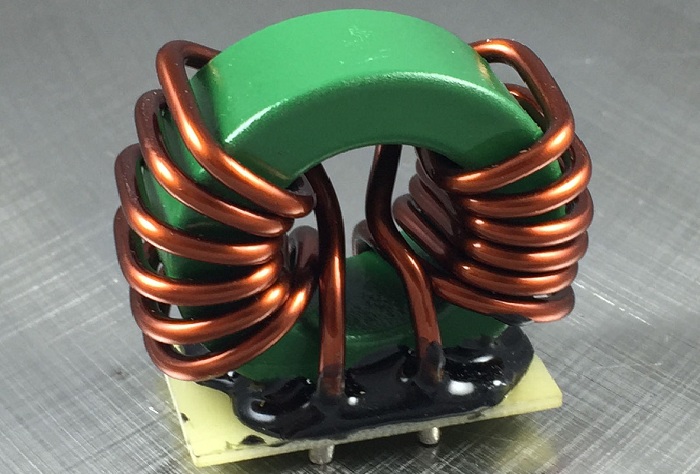

- Inductor Size and Shielding The application will determine the size of the inductor. Power circuits, for example require large inductors while RF applications use smaller ferrite core inductors. Large inductors must be compatible with filter capacitors. RF devices have lower power requirements. All inductors need shielded components to reduce magnetic coupling between components.

- Tolerance Percentage By studying the manufacturer's datasheet, engineers can compare tolerance percentage with a device's inductive value.

When you need to acquire an inductor, it's imperative to check the manufacturer's datasheets to make sure specifications correspond with applications. It's important to choose the most appropriate inductor for maximum performance and efficiency.