Thin Film Inductors: Design, Features, and Applications

Inductors are useful in electronic devices for filtering, timing, powering equipment and storing energy. They can store energy such as magnetic fields when currents flow through the device. Additionally, they can control currents through electromagnetic forces (EMF). A coil wound around a core is the basic foundation of inductors, in which there are various types of applications. Here are some important characteristics of thin film inductors, custom inductors and how they work.

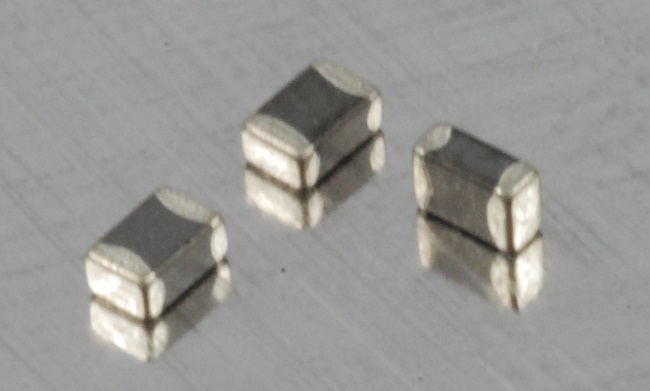

Design Film inductors are based on small thin film coils shaped like spirals with limits on maximum value. They are designed similarly to how semiconductors are manufactured, usually made from alumina, ferrite or magnetic material. This material allows for compact and higher precision performance. Some of the key benefits of designs using thin film include more stability, lower noise and heat resistance.

There are multiple ways to construct thin film inductors, as custom designs are often needed for proprietary communications applications. For example, instead of combining a resistor and inductor, thin film is capable of merging the two components into one, which can conserve current size and weight.

How It Works The inductance in an inductor depends on the amount of turns, area, length and material of the coil. With thin film inductors, numerous spiral-shaped thin film coils are placed on a substrate, which is the layer that facilitates the inductance process. Due to low height, thin film allows for improved electrical stability and resistance to vibration.

Features of Thin Film Inductors

- multilayer structure

- high accuracy coil based on micro-processing technology

- high performance compact chips

- stable inductance

- high Q or quality factor (lower rate of stored energy loss)

- high SRF (superconducting radio frequency) for RF current matching

Applications of Thin Film Inductors

- lightweight mobile communication devices

- wireless and LAN networks

- power supplies

- amplifiers

- voltage controlled oscillators

- impedance matching

- extreme repeatability

- tight tolerances

Conclusion Demand is growing for thin film inductors and custom inductors due to increasing proliferation of RF technology. Part of the attraction is due to their ability to adapt to properties of frequency-spectrum crowding. They are useful to achieve maximum bandwidth for wireless applications.